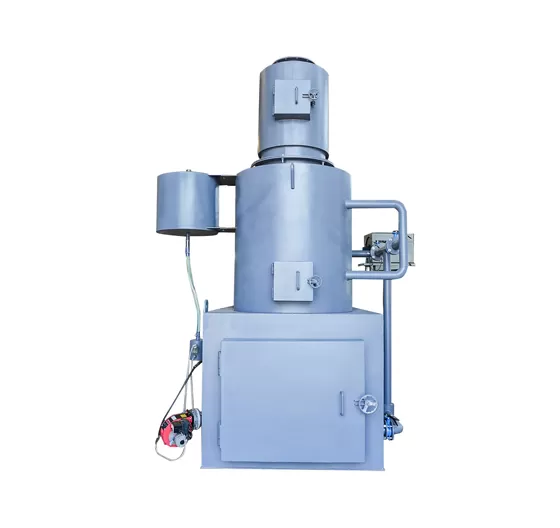

A packaging waste incinerator is a specialized waste management device designed to efficiently and safely dispose of packaging waste through hightemperature combustion. This method not only significantly reduces waste volume but also minimizes environmental impact by converting waste into ash and gases. The incineration process typically operates at temperatures between 800°C and 1,200°C, ensuring complete combustion and the destruction of harmful substances.

1. HighTemperature Combustion:

Incinerators use high temperatures (800°C to 1,200°C) to break down packaging waste materials, reducing their volume by up to 90% and weight by 8085%. This process ensures that waste is thoroughly decomposed, leaving minimal residue.

2. Emission Control:

Modern incinerators are equipped with advanced air pollution control systems, such as scrubbers and filters, to capture and neutralize harmful emissions like sulfur dioxide (SO₂), nitrogen oxides (NOₓ), and particulate matter (PM). These systems help ensure compliance with environmental regulations and minimize air pollution.

3. Energy Recovery:

The heat generated during incineration can be harnessed to produce steam, which can then be used to generate electricity or heat buildings. This wastetoenergy conversion not only reduces reliance on fossil fuels but also lowers greenhouse gas emissions.

4. Dual Chamber Design:

Many incinerators feature a dualchamber design, with a primary chamber for initial combustion and a secondary chamber for complete combustion of gases. This design ensures thorough burning and reduces the production of harmful byproducts like dioxins.