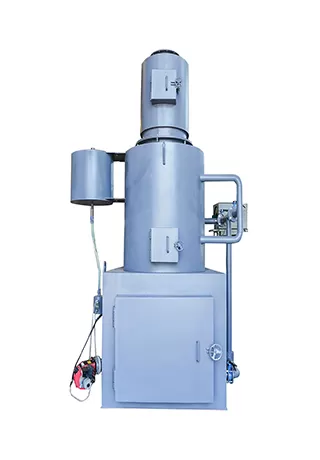

The XJY series medical waste incinerator employs the most advanced combustion method, which includes primary pyrolysis gasification, surrounding air mixed combustion, secondary incineration, and burnout treatment. The design of the primary combustion chamber utilizes gasification incineration technology, which raises the internal temperature of the incinerator from 200°C to 400°C. This prevents issues such as slagging, clinkering, and sintering during the incineration process. Compared to direct combustion furnaces and other types of furnaces, the gasification incinerator produces very little dust. The secondary mixed combustion chamber is equipped with secondary combustion burners and circumferential air supply. At high temperatures, combustible gases in the flue gas can fully combust, efficiently mixing the gases produced by the gasification furnace with air, preventing carbon overflow and delayed combustion. When the flue gas enters the high-temperature burnout chamber, tangential entry and auxiliary combustion air methods are used, allowing the flue gas to fully combust again while utilizing rotational airflow for dust removal. The flue gas remains in the furnace for about 2 seconds, ensuring complete combustion of combustible gases and fly ash.