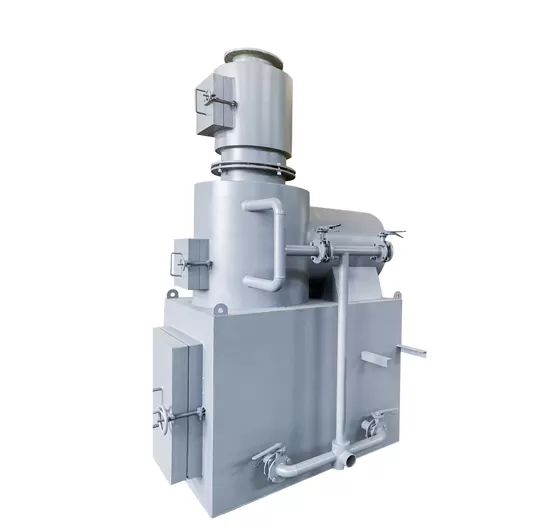

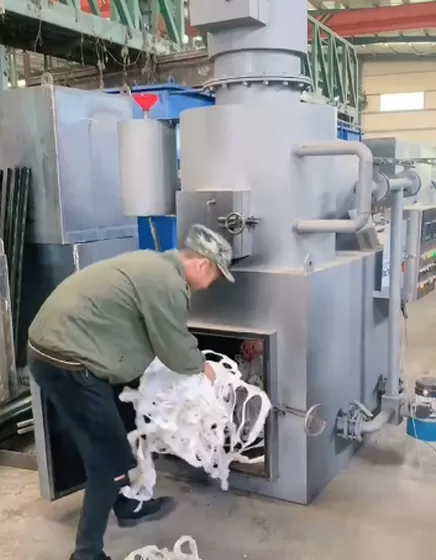

An industrial waste incinerator is a specialized facility designed to safely and efficiently dispose of a wide range of industrial waste materials through high-temperature combustion. These industrial trash/waste/garbage incinerators play a crucial role in managing hazardous and non-hazardous waste generated by various industries, ensuring compliance with environmental regulations while reducing the environmental impact of waste disposal.

Key Features and Functions of Industrial Waste Incinerator

High-Temperature Combustion

Industrial waste incinerators operate at extremely high temperatures, typically ranging from 800°C to 1,200°C (1,472°F to 2,192°F). This high-temperature environment ensures the complete combustion of waste materials, breaking down complex organic compounds and reducing waste volume by up to 90%. The intense heat also neutralizes pathogens and hazardous substances, making incineration an effective method for managing infectious and toxic waste.

Emission Control

Modern industrial waste incinerators are equipped with advanced air pollution control systems to minimize the release of harmful pollutants. These systems include:

Scrubbers: Wet or dry scrubbers are used to neutralize acidic gases such as sulfur dioxide (SO₂) and nitrogen oxides (NOₓ).

Filters: Particulate filters capture fine ash and other solid particles, reducing emissions of particulate matter (PM).

Catalytic Converters: These devices help break down volatile organic compounds (VOCs) and other harmful substances into less harmful byproducts.

These control systems ensure that industrial waste incinerators meet strict environmental regulations and minimize their impact on air quality.

Energy Recovery

One of the significant advantages of industrial waste incinerators is their ability to recover energy from the combustion process. The heat generated can be used to produce steam, which can then drive turbines to generate electricity or be used directly in industrial processes. This waste-to-energy conversion not only reduces the need for fossil fuels but also lowers greenhouse gas emissions, contributing to a more sustainable energy mix.

Types of Industrial Waste Incinerators

Controlled Air Incinerators

Controlled air incinerators regulate the air supply during combustion to maintain optimal burning conditions. This precise control ensures complete combustion and reduces the formation of harmful by-products. These incinerators are widely used for their reliability and efficiency in handling a variety of waste materials.

Excess Air Incinerators

Excess air incinerators use a surplus of air to ensure complete combustion, particularly useful for waste with high moisture content or low calorific value. The additional air helps maintain high temperatures and ensures thorough burning of waste materials.

Rotary Kiln Incinerators

Rotary kiln incinerators are advanced systems capable of handling large volumes of waste, including irregularly shaped materials. The rotary motion of the kiln ensures uniform mixing and complete combustion of waste materials. These incinerators are often used in industries that generate complex and varied waste streams.